-

Resource Circularity

Efforts to Reduce Environmental Impact

As part of its environmental policy to reduce the environmental impact of its business activities, JDI is promoting various initiatives such as the reduction of industrial chemicals, the reduction of sludge, the reduction of water consumption, and the reduction of VOC emissions at each manufacturing site.

Actions for Reducing Environmental Impact

Recycling of Waste Materials

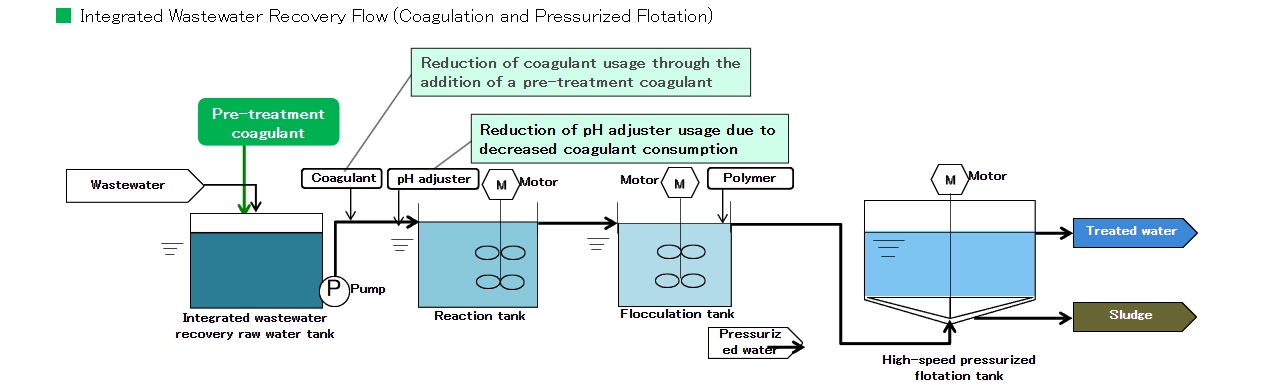

At the Mobara Fab, wastewater from production equipment is treated and reused as raw water for pure water. During the treatment process, a large amount of industrial chemicals (coagulants, pH adjusters) are used. As a result of the treatment, a large amount of sludge (industrial waste) is also generated. This time, by adding a small amount of a “pre-treatment coagulant” with nearly 100 times the charge neutralization power of conventional coagulant, the amount of coagulant used was reduced by 50%. As a result, the amount of pH adjuster required to neutralize the acidic coagulant and the amount of sludge generated were reduced by 20%.

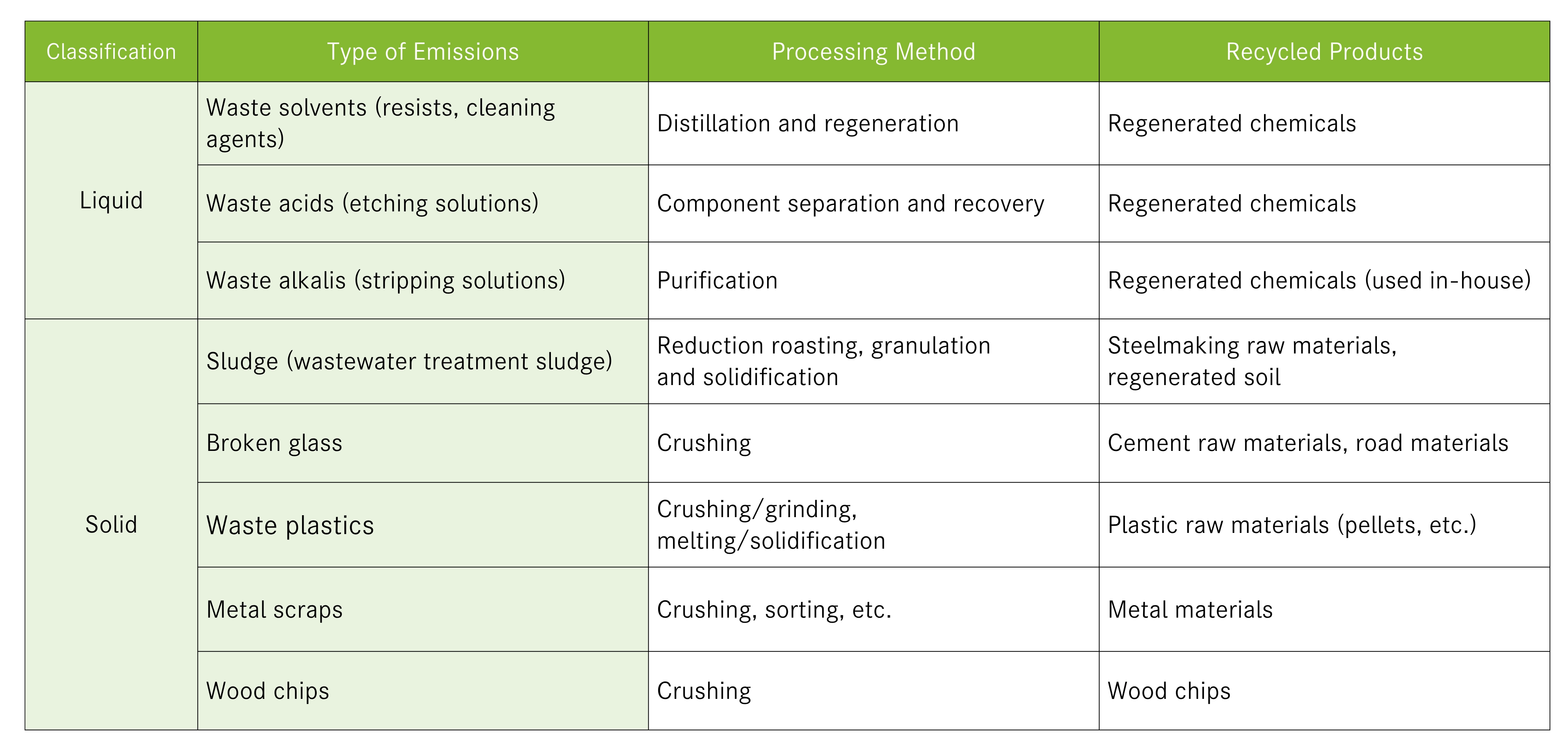

Promoting the Recycling of Waste

From the perspective of resource circulation, JDI aims to recycle waste (both valuable and discarded materials) as much as possible. The main details regarding the Mobara fab are outlined in the table below. Additionally, for waste that undergoes neutralization or incineration by JDI’s business partners (disposal companies), JDI strives for further recycling into materials such as regenerated sand and roadbed materials. Furthermore, waste-to-energy generation (heat recovery) is also implemented during incineration.