Next Generation OLED

eLEAP

Overturning Conventional Wisdom and Leaping into the Future. Next-generation OLED Displays Made Possible by Groundbreaking Manufacturing Technology

eLEAP is an OLED display manufactured without using the traditional metal mask, leveraging our established design and process know-how. While retaining the features of OLED displays such as thinness, lightness, high contrast, and fast response, it has significantly expanded the light-emitting area compared to traditional OLED displays. It solves the burn-in issues that often occur in the market and its high processing accuracy is expected to be applied to high-definition displays.

01 Triple the Lifespan, Double the Brightness. Any Design is Possible

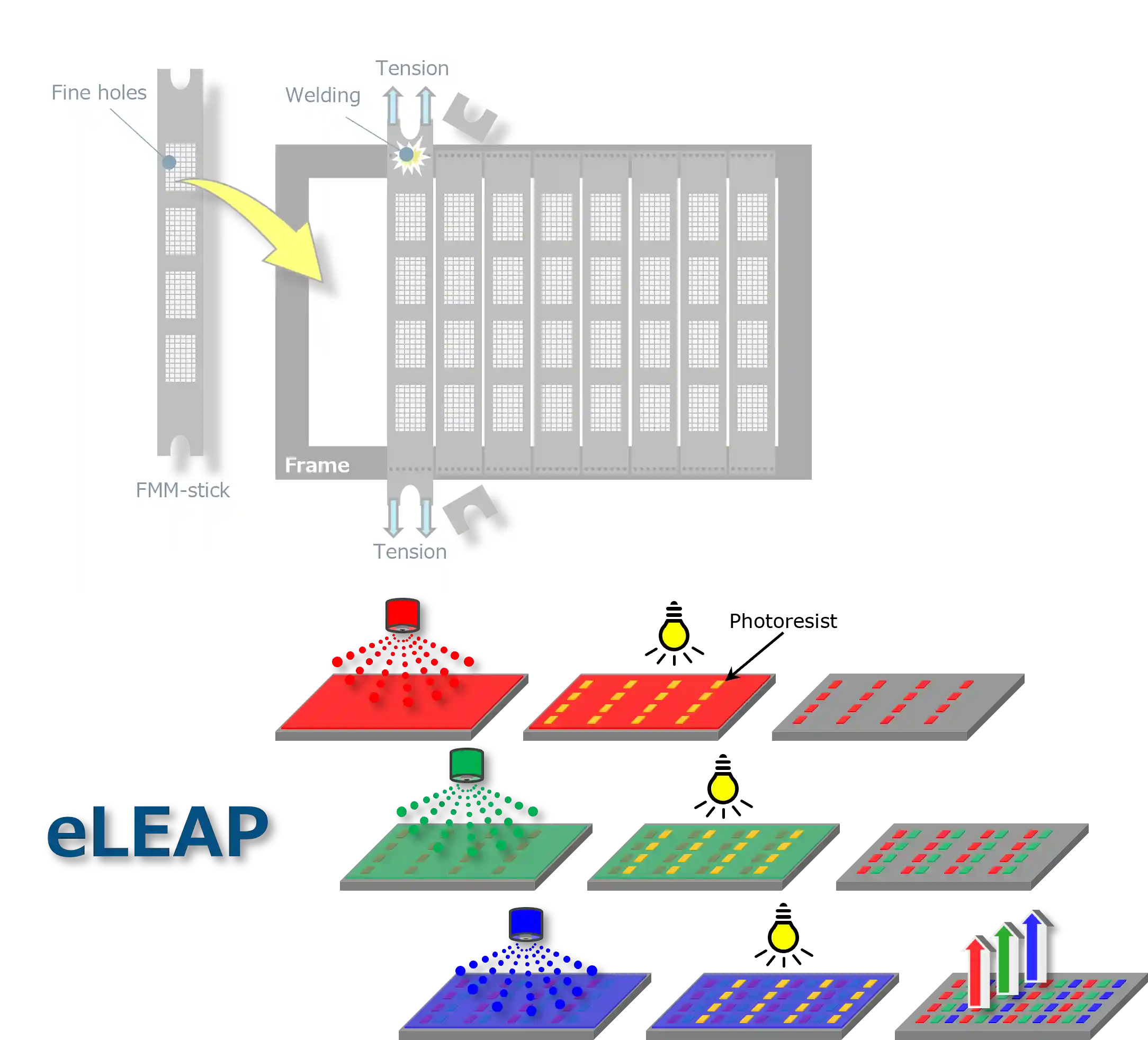

A car interior? A frog-shaped TV? With the metal mask-free eLEAP, you can realize any shape you desire. It is the first in the world to achieve an aperture ratio of over 60%, which is twice the light-emitting area of conventional OLED displays. If used at the same brightness as before, it has three times the lifespan and reliability. Even if used at twice the brightness, it can maintain the same level of lifespan and reliability as before.

02

The traditional fine metal mask used in the OLED display manufacturing process requires a large amount of organic material and needs to be cleaned for reuse, but eLEAP does not use fine metal masks at all. Assuming a monthly production of 30,000 sheets on a sixth-generation glass substrate, it can reduce carbon dioxide emissions by 150,000 tons per year, which is equivalent to the absorption amount of 17 million cedar trees per year.

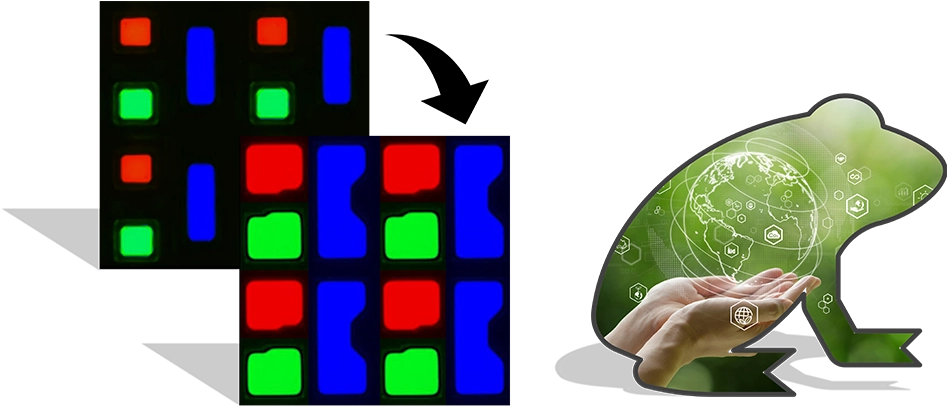

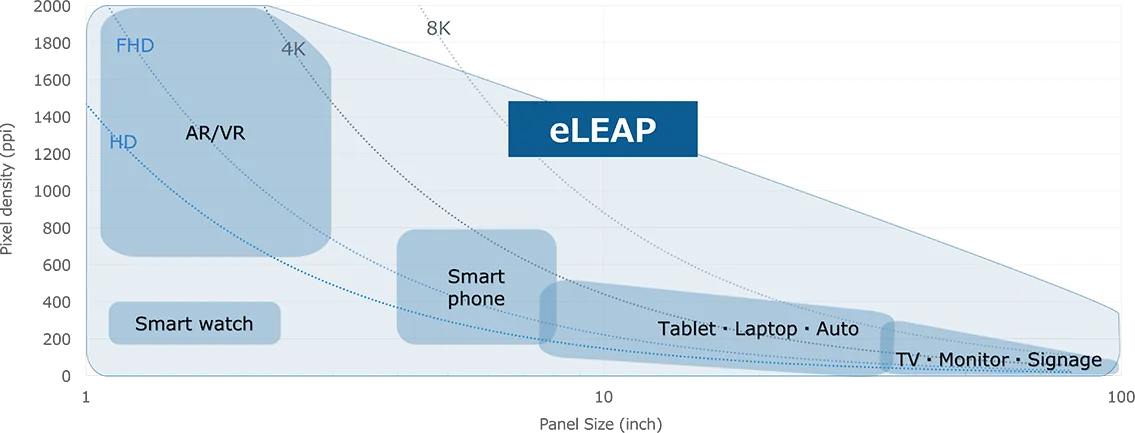

03 Providing New Value in All Categories

With eLEAP, it is possible to realize large-scale and high definition, which was difficult to achieve with traditional OLED displays that use a metal mask in the manufacturing process. It's an innovative OLED display that adds value to all product categories.

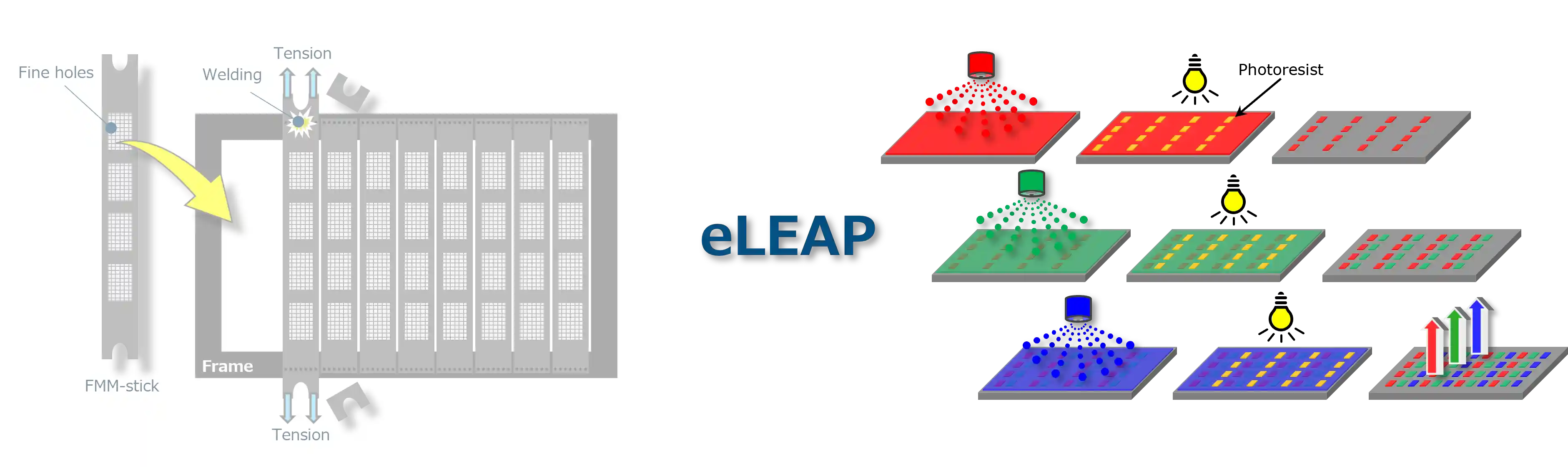

Currently, the fine metal mask (FMM) evaporation method (hereinafter referred to as "conventional FMM method") is widely adopted for mass production of OLED displays, but eLEAP is an OLED display that deposits organic materials on the substrate without using FMM at all and forms OLED pixels by the photolithography method. The light-emitting area of eLEAP is more than twice that of OLEDs by the conventional FMM method, increasing to 60% (equivalent to 300ppi, compared to current JDI products), and it has been possible to dramatically improve the lifespan, which has been a weak point of OLED displays. In addition, free-form design, high-definition exceeding 800ppi, and enlargement of display size, which were difficult in the conventional FMM method due to the constraints of using fine metal masks, have also become possible. In addition, eLEAP, which does not use a metal mask, can be scaled up to 8th generation substrate lines (approximately 2200mm x 2500mm) and beyond, and can accommodate display sizes from small to large using the same manufacturing process. Furthermore, one of the problems with the conventional FMM method is that a large amount of organic solvent is required to clean the organic material adhering to the FMM during production, resulting in material disposal loss. The manufacturing process of eLEAP significantly suppresses the amount of organic solvent used by not using FMM, which is a green technology that can reduce CO2 emissions. In this way, eLEAP surpasses OLED displays by the existing FMM method in all features and has already attracted high interest and specific inquiries from multiple customers as an OLED display that brings about a dramatic change, and a rapid expansion of demand is expected in the future. We have started shipping samples and expect a gradual increase in shipment volume. In addition, we plan to license this Global No.1 proprietary technology to other companies, with the aim of achieving a significant increase in sales and a major contribution to society.